VITROCELL ® Smoking Machines

VITROCELL ® 흡연 기계는 다양한 기타 연구 작업뿐만 �아니라 체외 실험의 요구 사항을 충족하도록 설계되었습니다. 모든 VITROCELL ® 담배 흡연 기계 및 흡연 로봇은 전체 연기, 기체 상태 및 부류 연기를 정확하게 생성하는 데 적합합니다. 모든 기계는 특수 전자 담배 제품 패키지를 통해 전자 담배도 처리할 수 있습니다.

VITROCELL®Smoking Machine VC 1/7

7개의 개별 프로그래밍 가능한 주사기 드라이브가 있는 기존 및 전자 담배용 선형 흡연 기계.

선형 흡연 기계 VC 1/7은 체외 실험의 요구 사항을 충족하도록 특별히 설계 및 제조되었습니다. 기존 및 전자 담배에 적합합니다.

흡연 기계에 대한 이 새로운 개념은 다른 상업용 흡연 기계에 비해 상당한 이점을 제공합니�다.

Generation of smoke with the shortest distance to cell cultures

For the success of an experiment with whole aerosol it is vital that the distance between the aerosol generation (cigarette holders) and the VITROCELL® cell exposure system is as short as possible to guarantee authentic aerosol-composition.

Open and flexible system / incorporation of other analytical tools

The VC 1/7 machine is designed to allow easy access to all tubes, filters and the pumping system. Additional analytical equipment relevant to the experiment can be easily and individually installed.

Freely programmable parameters

The computer system facilitates highly flexible programming of the smoking process. All parameters of the smoking process like puff duration, puff volume, puff frequency and exhaust duration can be defined according to experiment requirements

High flexibility for all smoking regimes

Square, ISO, Health Canada Intense, Massachusetts and Human Puff Profile regimes (option) can be smoked.

Statistics

Smoking process data are logged into an Excel® sheet for further processing.

Machine dimensions are suitable for constrained lab workspace

Machine dimensions are suitable for constrained lab workplaces The VC 1/7 machine is divided into 3 major components: computer, control box, syringe drives and cigarette holder systems.

All components are easy to clean

In particular the work with unfiltered aerosol demands frequent cleaning of all machine parts which come into contact with the constituents. Easy access to all component ensures quick and efficient cleaning.

Human puff profile capability

This optional feature offers the possibility to feed data of human puff profiles registered by Smoking Puff Analyzers to the machine controls.

Compatibility with existing lab systems

The VC 1/7 machine can be integrated with and connected to other lab systems, e.g. analytical systems.

Compliance with all current e-cigarette regimes

The VC 1/7 is able to generate aerosol with puff volumes up to 200 ml using square profiles and all relevant time settings.

Compliance with ISO 3308:2012

The VC 1/7 machine meets the requirements of ISO 3308:2012, which assures compatibility with data generated for quality assurance purposes on other smoking machines.

Compliance with Health Canada / Intense Conditions

The VC 1/7 machine meets the requirements for 55 ml/30 sec puff frequency requirements.

Quality

The VC 1/7 machine is built to the highest standards using reliable and durable components. Precision of the process is ensured by linear motor drives for the piston.

Service

All VC 1/7 machines are specifically designed to be exceptionally service-friendly and have a secure internet-based remote servicing module.

Software Control

Input is communicated via PC with flat screen monitor or laptop (part of delivery).

Highly flexible modes of operation

Mode 1 for e-cigarettes

Direct connection of draw-actuated cigarettes to the syringe drives.

Mode 2 for e-cigarettes

7 individual vapestarter units with button activators for tank products are connected to the syringe drives.

Mode 1 for e-cigarettes

7 individual smoke boxes allow for smoking of combustion cigarettes. Integrated butt length sensors.

More about VC 1/7

Smoking parameters

The following parameters can be adjusted according to the needs of the experiment: Puff and exhaust duration, Puff frequency, Puff volume, Puff profile, Flow rate, Clearing puff number, Puff duration hold time, Butt length via sensor

Unique syringe drive system

Linear motor drive system with lowest dead volume and easy cleaning features. Each syringe drive can be programmed with an individual regime.

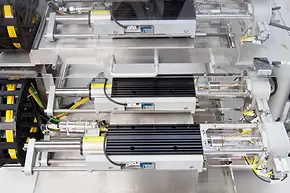

State of the art controls for the 7 syringe drives to highest precision

Drawer with linear motor drives

Option: VITROCELL Vapestarter

Innovative solution for smoking machines: automatic button activation of e-cigarettes

Option: Human Puff Profiles

Data generated by a Smoking Puff Analyzer is directly loaded to the controls of the machine.

Option: Special Holder System for e-Cigarettes

Option: Secure and tight connection of any puff-actuated device

Option: Human Puff Profiles

Innovative solution for smoking machines: automatic button activation of e-cigarettes.

Technical Data

-

Dimensions: Mounted on cart 1.800 x 800 x 1.530 mm (L x W x H)

-

Voltage: 3 x 400 V, 50/60 Hz, or power converter 3 x 208 V, 16 A (C)

-

Compressed air: 6 bar (87 psi) min.

-

Remote service module: Included / Internet access mandatory

VITROCELL® Smoking Robot VC 10

흡연 기계 VC 10 ® 은 체외 실험을 위한 전체 연기 및 에어로졸 생성 요구 사항을 충족하도록 특별히 설계되었습니다. 기존 및 전자 담배에 적합합니다.

VC 10 ® 은 다른 상업용 흡연 기계에 비해 상당한 이점을 제공합니다.

Generation of smoke with the shortest distance to cell cultures

For the success of an experiment with mainstream tobacco smoke it is important that the distance between the smoke generation (cigarette holders) and the VITROCELL® cell cultivation and exposure system is as short as possible in order to avoid aging and to guarantee a smoke composition matching the real-life situation.

Open and flexible system / incorporation of other analytical tools

The robot is designed to allow easy access to all tubes, filters and the syringe system. Additional analytical equipment relevant to the experiment can be installed without difficulty by the operator.

Freely programmable parameters

The computer system allows highly flexible programming of the smoking process. All parameters of the smoking process like puff duration, puff volume, puff frequency and exhaust duration can be defined according to the needs of the experiment.

Statistics

The data of the smoking process are logged into an Excel® sheet for further processing.

Machine dimensions are suitable for constrained lab workplaces

The robot is divided into 3 major components: computer, control box and smoking platform. Only the smoking platform must be placed in the direct area of the experiment, the other components can be placed elsewhere in the lab.

All components are easy to clean

In particular the work with unfiltered mainstream smoke demands frequent cleaning of all parts of the robot which are in contact with the smoke. Cleaning must take place after each experiment in order to avoid any influence of residual products on the following experiment. Due to the easy access to all parts the cleaning can be done quickly and efficiently.

Compatibility with other systems in the lab

The robot can be integrated with and connected to other lab systems, e. g. analytical or automation systems.

Compliance with ISO 3308:2012

The VC 1 S-TYPE machine meets the requirements of ISO 3308:2012 which assures a compatibility with data generated for quality assurance purposes on other smoking machines.

Compliance with Health Canada / Intense Conditions

The VC 1 S-TYPE machine meets the requirements for 55 ml/30 sec puff frequency requirements if the interchange option is purchased.

Bell shaped, square and human puff profile capabilities

Quality

The VC 10 machine is built to the highest standards using reliable and durable components. Precision of the process is ensured by a linear motor drive for the piston.

Service

All VC 10 machines are designed to be very service-friendy and have a secure internet-based remote servicing module

VC 10 Operation

Magazine

The standard magazine takes up to 20 cigarettes and larger versions are also available. They are suitable for storage in the climatization chamber for pre-conditioning of the cigarettes.

Automatic leak detector

There is the option to activate the leak detector prior to each experiment. The detector confirms the tightness of the system including cigarette holders and pump. The results are logged in the study files.

Loading unit

The standard magazine takes up to 20 cigarettes and larger versions are also available. They are suitable for storage in the climatization chamber for pre-conditioning of the cigarettes.

Special Holder System for e-Cigarettes

Secure and tight connection of any puff-actuated device.

Option: VITROCELL Vapestarter

Innovative solution for smoking machines: automatic button activation of e-cigarettes.

Ignition and smoking

Lighter

The electric lighter ensures the automatic ignition and a safe procedure without cigarette damage.

Syringe drive

The syringe pump is controlled by a linear motor with high precision. The pump can be dismantled for cleaning and refitted again in a few minutes.

Loading unit

Stepper motor for rotation of port holderfitted again in a few minutes.

The rotation of the port holder is controlled by a stepper motor with highest precision.

The Cambridge filter can be mounted easily into the system for analytical purposes.

Smoking and butt extraction

Hood for sidestream smoke evacuation

The integrated fan evacuates the sidestream smoke. The air flow at the cigarette holders is adjusted by the fan speed.

Butt length sensor

The IR-sensor can be adjusted to a fraction of a millimeter and transmits reliable signals to the pump and butt extractor. If the critical butt length is reached, the pump stops immediately. Alternatively, it is also possible to work with a defined number of puffs.

Butt extractor

The cigarette is forwarded to the extraction position and removed from the holder. The ashtray is kept permanently clean with a brush.

Software and Controls

Smoking parameters

The operation is controlled by Beckhoff software in conjunction with Microsoft Windows 10®. This setup offers extensive possibilities for integration with common Microsoft Office® applications and the exchange of data with Excel®-sheets.

Advanced, user-friendly software with recipe edit functions for favorite smoking / vaping regimes :

puff volume: up to 200 mL

> puff frequency: 4 – 250 s

> puff duration: 0.1 – 15 s

> puff exhaust duration: 0.5 – 15 s

> number of cigarettes per run: 300

> number of puffs: 1-250

> smoking modes: single, cycle, serial

> profiles: bell, square, human

Smoking modes :

Single, cycle and serial mode

> Pre-loading mode

> Lighter off mode

> Cycle mode with system purging after each cycle

Technical Data

-

Dimensions electrical control box: 600 x 300 x 600 mm (L x W x H); 24 x 12 x 24 inches

-

Dimensions smoking platform: 1000 x 600 x 300 mm (L x W x H) / (height without hood); 40 x 24 x 12 inches

-

Power supply: 1 x 230 V, 50/60 Hz , 16 A

-

Compressed air: Operating pressure 6 bar (87 psi); system pressure 10 bar (145 psi)

-

Remote service module: Included / Internet access mandatory

VITROCELL® Smoking Robot VC 10 S-Type

첨단 기술로 인해 VITROCELL ® 훈연기 VC 10 ® S-TYPE은 일반 담배와 전자 담배를 평가하기 위한 완벽한 도구입니다.

이 흡연 기계는 고급 연구를 위한 모든 특수 요구 사항을 갖추고 있습니다: ISO, 캐나다 보건부 및 사각 퍼프 프로필 프로토콜 준수, 취급 용이성, 빠른 세척 및 고속 제품 교체 기능.

측면 및 주류 연기 작업에 적합하며 다른 흡연 기계에 비해 상당한 이점을 제공합니다.

Generation of smoke with the shortest distance to cell cultures

For the success of an experiment with mainstream tobacco smoke it is important that the distance between the smoke generation (cigarette holders) and the VITROCELL® cell cultivation and exposure system is as short as possible in order to avoid aging and to guarantee a smoke composition matching the real-life situation.

Open and flexible system / incorporation of other analytical tools

The robot is designed to allow easy access to all tubes, filters and the syringe system. Additional analytical equipment relevant to the experiment can be installed without difficulty by the operator.

Freely programmable parameters

The computer system allows highly flexible programming of the smoking process. All parameters of the smoking process like puff duration, puff volume, puff frequency and exhaust duration can be defined according to the needs of the experiment.

Statistics

The data of the smoking process are logged into an Excel® sheet for further processing.

All components are easy to clean

In particular the work with unfiltered mainstream smoke demands frequent cleaning of all parts of the robot which are in contact with the smoke. Cleaning must take place after each experiment in order to avoid any influence of residual products on the following experiment. Due to the easy access to all parts the cleaning can be done quickly and efficiently.

Compatibility with other systems in the lab

The robot can be integrated with and connected to other lab systems, e. g. analytical or automation systems.

Compliance with ISO 3308:2012

The robot meets the requirements of ISO 3308:2012 which assures a compatibility with data generated for quality assurance purposes on other smoking machines.

Compliance with Health Canada / Intense Conditions

The robot meets the requirements for 55 ml/30 sec puff frequency requirements.

Bell shaped, square and human puff profile capabilities

Quality

The robot is built to the highest standards using reliable and durable components. Precision of the process is ensured by a stepper motor for smoking port rotation and linear drive motor for the pump as well as sensor-controlled and pneumatically-driven components. Compliance with CE standards.

Service

All VC 10® robots are designed to be very service-friendy and have a secure internet-based remote servicing module.

Special features of the VITROCELL VC 10 S-TYPE Smoking Robot

-

Platform concept with docking stations

-

Large magazine for 300 cigarettes enabling long test runs

-

New smoking head with small dead volume and integrated butt ejector

-

Quick-lock holder system for all types of conventional and e-cigarettes

-

Machine-controlled button actuator for e-cigarettes

-

Heated smoke path system

-

New multiple 5-port exhaust system

-

Scalable to up to 3 syringe drives

-

Entire product change cleaning in < 10 min (with a few prepared exchange parts)

VC 10 S-TYPE Operation for e-cigarettes

Quick-lock holder system with e-cigarette support crown

The holders can be quickly exchanged for cleaning and the support crown holds heavier e-cigarettes safely.

Special Holder System for e-Cigarettes

Secure and tight connection of any puff-actuated device.

Heated smoke path

The smoke path can be heated and temperature controlled to avoid eventual condensation.

Option: VITROCELL Vapestarter

Innovative solution for smoking machines: automatic button activation of e-cigarettes.

VC 10 S-TYPE Operation for conventional cigarettes

Magazine

The magazine stores up to 300 cigarettes and has a machine-controlled feeding and aligning system.

Automatic leak detector

There is the option to activate the leak detector prior to each experiment. The detector confirms the tightness of the system including cigarette holders and pump. The results are logged in the study files.

Loading unit

Damage-free loading of the cigarettes into the cigarette holders takes place fully automatically. The cigarette holders are equipped with labyrinth seals as required by ISO 3308:2012.

Ignition and smoking

Lighter

Safe and contact-free lighting of the cigarettes. Designed for maintenance-free operation.

Cambridge filter

The Cambridge filter can be mounted easily into the system for analytical purposes.

Stepper motor for rotation of port holder

The rotation of the port holder is controlled by a stepper motor with highest precision.

Smoking and butt extraction

Hood with sidestream smoke ducts

The integrated fan evacuates the sidestream smoke. The air flow at the cigarette holders is adjusted by the fan speed.

Butt length sensor

The IR-sensor can be adjusted to a fraction of a millimeter and transmits reliable signals to the pump and butt extractor. If the critical butt length is reached, the pump stops immediately. Alternatively, it is also possible to work with a defined number of puffs.

Butt ejector

The cigarette butts are removed from the holder by ejection. The ashtray is kept permanently clean with a brush.

Large butt reservoir

The butts are forwarded into a large reservoir.

Linear motor for syringe drive

Syringe drive

The syringe pump is controlled with high precision by a strong linear motor. Due to the special design, the syringe can be dismantled for cleaning and refitted again in a very short time.

The machine can be scaled up to 3 syringe drives to increase the puff frequency.

Unique 5-port exhaust system

5 individual machine-controlled exhaust lines direct the smoke to 5 dilution systems.

Software and Controls

-

Electrical control box

-

The control box houses the controls for the stepper motors, sensors and pneumatic valves. The whole process is controlled by Beckhoff software in conjunction with Microsoft Windows 10®. This setup offers extensive possibilities for integration with common Microsoft Office® applications and the exchange of data with Excel®-sheets.

Smoking parameters

The operation is controlled by Beckhoff software in conjunction with Microsoft Windows 10®. This setup offers extensive possibilities for integration with common Microsoft Office® applications and the exchange of data with Excel®-sheets.

Advanced, user-friendly software with recipe edit functions for favorite smoking / vaping regimes :

puff volume: up to 200 mL

> puff frequency: 4 – 250 s

> puff duration: 0.1 – 15 s

> puff exhaust duration: 0.5 – 15 s

> number of cigarettes per run: 300

> number of puffs: 1-250

> smoking modes: single, cycle, serial

> profiles: bell, square, human

Smoking modes :

Single, cycle and serial mode

> Pre-loading mode

> Lighter off mode

> Cycle mode with system purging after each cycle

Technical Data

-

Dimensions electrical control box: 790 x 300 x 600 mm (L x W x H); 31 x 12 x 24 inches

-

Dimensions smoking platform: 940 x 690 x 670/694* mm (L x W x H) / (height without hood); 37 x 28 x 27/28 inches

-

Power supply: 1 x 230 V, 50/60 Hz , 16 A

-

Compressed air: Operating pressure 6 bar (87 psi); system pressure 10 bar (145 psi)

-

Remote service module: Included / Internet access mandatory

-

*platform opened

_edited.png)